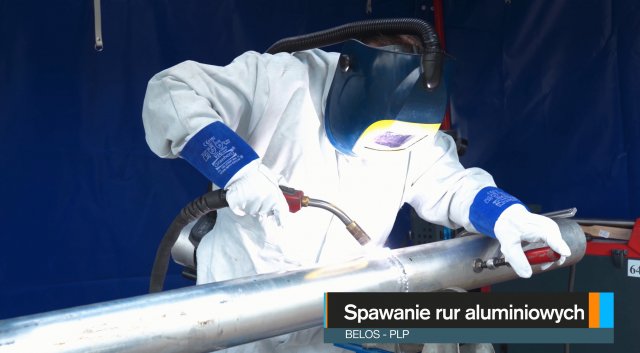

We weld butt joints and fillet joints in accordance with the standard: PN-EN ISO-10042.

We also weld tubes on site,Our welders will be available for you on the agreed date and time.

We offer welding services globally.

It is worth mentioning that our welding services meet all the standards related to safety at work.

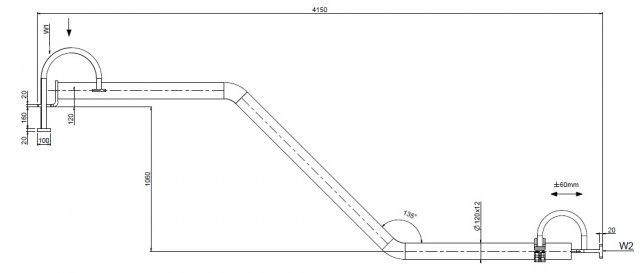

We design and install tube joints in power substations.

We have been welding aluminium plates, rods and tubes with different cross-sections for 70 years.

We have completed most of the investments for the Polish electricity operator (Polskie Sieci Energetyczne).

All investment projects are completed on time.

Data required for the estimation of welding operations on site.

On the customer's request, non-destructive tests are performed by our qualified experts in accordance with the standard: PN-EN ISO-971.

Examples of projects:

- 132kV power substation in Ihovbor Nigeria

- 400/220/110kV power substation in Świebodzice

- 400/110kV power substation in Żydowo-Kierzkowo

Data needed for the valuation of welding on construction site:

- Construction site location

- Type of pipes

- Number of joints

- Completion date and time window for welding

- Statement on required tests in accordance with the standard: PN-EN ISO-9712

- Other (whether operations in the electromagnetic field, in adverse weather conditions, etc., are involved)

400/220/110kV power substation in Byczyna

TEST OF WELD JOINTS

We perform tests to find any problems, such as:

- material non-continuity,

- incorrect structure,

- incorrect geometry,

- no resistance to corrosion.

Welded joints made of aluminium alloys and steel are subject to non-destructive tests to confirm quality compliance with the requirements of specifications. Usually these include visual inspections (VT), penetrant tests (PT) and ultrasonic tests (UT). Tests are performed by experts which have the 2nd and 3rd level of qualifications according to ISO 9712. Welded joints on aluminium conductor rails, performed with the use of welding inserts, are subjected to ultrasound tests for the detection of porosity defects. In October 2016, BELOS-PLP developed a special testing procedure ”Ultrasonic testing for Aluminium Welds” which allows the detection of surface defects and the determination of porosity in aluminium joints. It is the only volumetric method of the verification of porosity when radiographic testing is not possible.

In Poland, this method is unique.